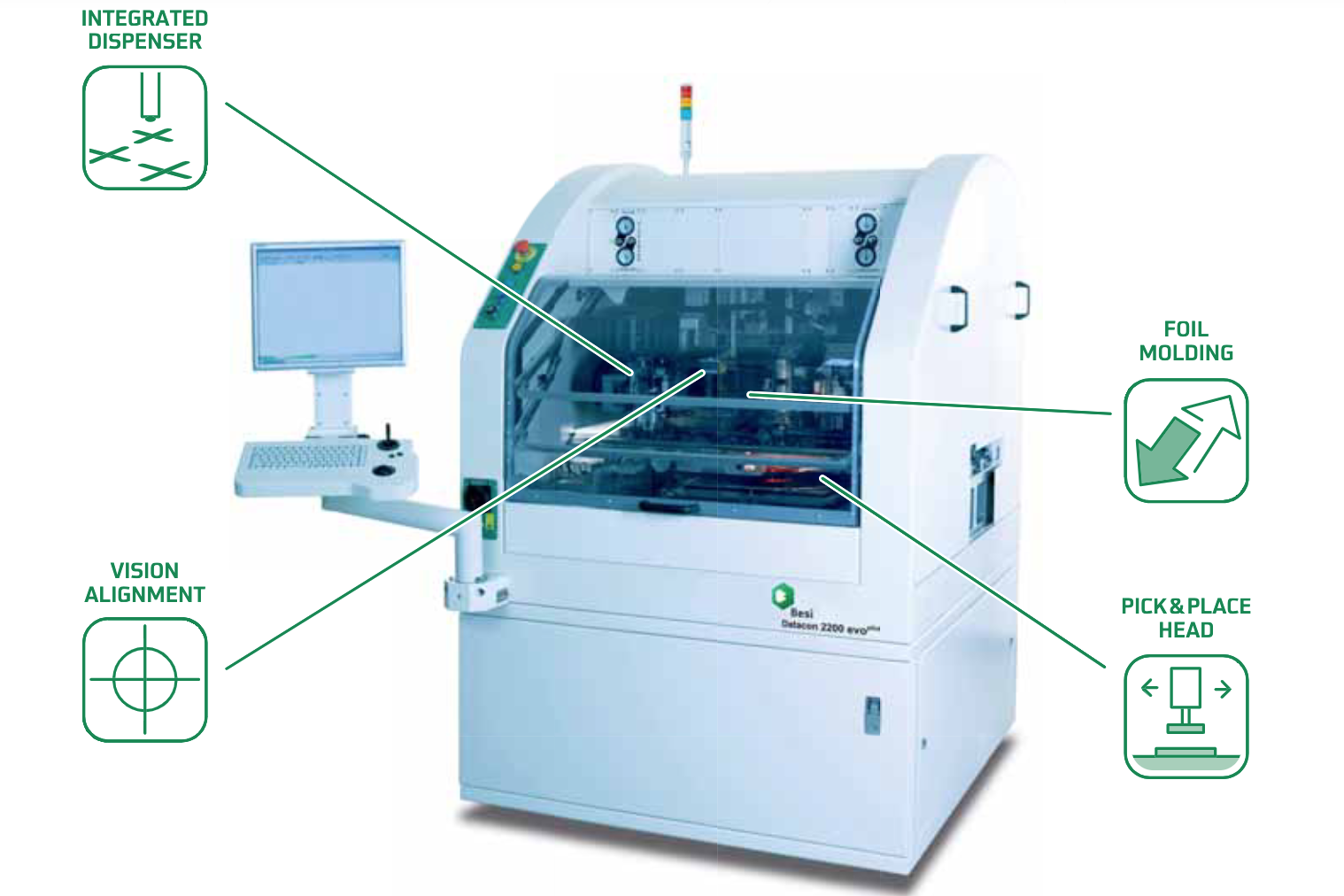

State-of-the-art Besi 2200 evo plus die bonder installed at Santa Clara facility

SANTA CLARA, Calif., Oct. 4, 2022 – Promex Industries, a Silicon Valley-based provider of advanced design, packaging and microelectronics assembly services, today announced it has completed the first phase of its plan to expand its die bonding services. The company has installed a new 2200 evo plus die bonder from BE Semiconductor Industries (Besi) on its production line, adding significant capacity, as well as enhanced accuracy, productivity and flexibility for customer projects targeting a range of key end markets, including medical, biotech and automotive.

The state-of-the-art 2200 evo plus joins Promex’s existing lineup of die bonders, including three additional Besi systems. The robustness and life expectancy of Besi tools, together with new capabilities integrated into the now fourth generation of the 2200 evo plus, contributed to its selection.

Chief among the benefits offered by the 2200 evo plus is its tremendous flexibility and the ability to deliver die attach, flip-chip and multi-chip capability in a single unit. It features an integrated dispenser for direct placement when performing die attach, and its advanced pick-and-place head enables the system to pick components directly from a wafer on tape or a waffle pack and place them as needed for the application.

Another key feature of the evoplus is its optional heated bond head and stage, contributing to its ability to accommodate a variety of substrates and materials, including die attach film (DAF). DAF has become essential in the heterogeneous integration (HI) era for use in wafer prep and singulation of wire-bonded single and multi-chip stacked die solutions. As HI applications involve combining electronic and non-electronic components, the new equipment is also highly capable for assembly of photonic and optical devices.

“Promex is a longtime customer, and their selection of our newest 2200 evo plus multi chip die bonder highlights the strength of our ongoing relationship and the confidence they place in our technology,” stated Hannes Hundsbichler, director for the Multi Chip Die Bonding product line with Besi. “We are proud to serve as one of their trusted suppliers.”

“Our Besi units have consistently delivered excellent results,” said Chip Greely, vice president of engineering for Promex. “With the addition of the 2200 evo plus system, we see great opportunity to secure a broader range of advanced die bonding projects from both new and existing customers.”

About Promex

Promex Industries, Inc. specializes in advanced design, packaging and assembly services for key subsystems used in a wide range of applications, such as optical, photonics, diagnostics, life sciences, medical and MEMS devices. The company is skilled at heterogeneous integration of tiny components with unique functionality and complex, custom or detailed assembly requirements. Founded in 1975, Silicon Valley-based Promex provides design-for-manufacturing services coupled with materials science expertise and broad assembly capabilities for small- to mid-volume onshore production. Services include RoHS-optimized SMT, wafer thinning, dicing, wire bonding, flip chip, and combining microelectronic and non-microelectronic components, provided in the company’s Class 100/Class 1000 cleanrooms. Promex holds a CA FDB license and is ISO 13485:2016 and ISO 9001:2015 certified, IPC certified and ITAR registered. https://promex-ind.com/