Promex specializes in the assembly and fabrication of complex medical devices and biotech instruments and consumables involving customized assembly processes for physically small medical and biotech devices. Devices that incorporate conventional microelectronic parts as well as specialized components requiring highly unique assembly processes.

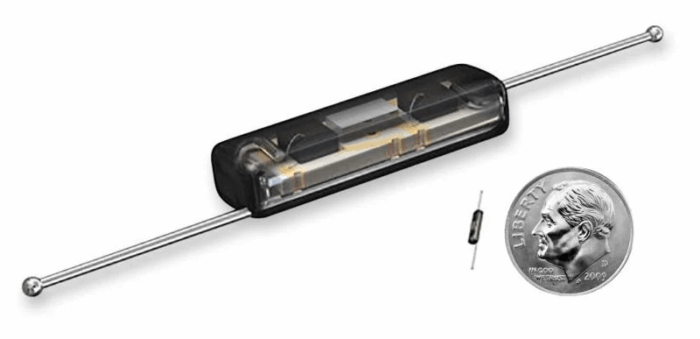

A recent project involved a medical device company that approached us with their implantable radio-frequency microelectronic device that needed to go to volume production of several thousand units per week.

The device was cylindrical with protruding biocompatible antennas and because it had to be injected through a hypodermic needle, was ultra-small at only 5-hundredths of an inch in diameter.

The customer was building the prototypes manually utilizing jewelry-making methods, one at a time under a microscope with hand tools. To reach full-scale production volumes, a more efficient manufacturing process was needed that could be scaled up while maintaining device quality and cost.

We helped develop a process in 10 by 16 arrays upon which the device was additively built up on the substrate using several high-accuracy assembly machines. Once the chips and antennas were properly interconnected and encapsulated, we singulated the panels into individual devices and finished with the application of a biocompatible coating.

Working closely with the client, we had this new component assembly process rapidly completed, resulting in a higher quality, scalable low-cost process suitable for high-throughput manufacture to FDA standards.

Promex understands the unique demands of medical device and biotech companies; reducing both your developmental risk and time to production while working within rigorous cost requirements. Offering biotech instrument and medical device companies a low-risk path from feasibility prototype development through to full production. All in a single fully integrated US-based component assembly facility located in the heart of Silicon Valley.

From small-scale prototype production demonstrating the viability of your basic technical concept, through to scaling those processes into full production, Promex offers a fully integrated suite of services. With a single partner, you can move from fabricating simple combinations of parts and measuring the result to eliminate development risks, through to full production. Meeting all the necessary requirements for FDA compliance and full manufacturing process validation, while still meeting rigorous cost requirements.

Let us know how we can turn your concept from working prototype to full-scale production.

Concept to Commercialization

Whether you need short-run proof-of-concept prototypes, high-volume production, or a second-source manufacturer, Promex can help. Reach out to us and let’s have a no-pressure conversation about how we might help advance your project to success.