by: Dick Otte, President & CEO

Ninety percent of contract manufacturers make devices that are little more than metal boxes with stuff in them. The other ten percent offer specialized processes. Then there is the rare breed of microelectronics assembly services provider that has mastered multiple layers of capabilities and combined them into one heterogeneous process. Like Promex.

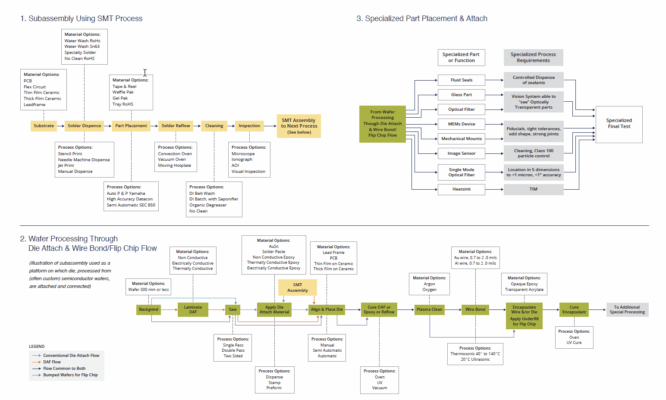

When we were founded 35 years ago, we could have gone the route of a “Tier One-wanna be,” caught in the endless circle of acquiring more equipment to support higher volumes. But we didn’t. Because even back in the early 1980s, it was apparent to us that conventional processes such as SMT would not always be the perfect solution.

So we hired engineers who were not only familiar with a wide variety of materials but were also well versed in mechanical and thermal design. They had to know about the latest fixturing developments. And most important, they had to be acquainted with the many evaluation methods used to ensure process control and high yield.

And we made a substantial investment in equipment that went beyond SMT lines. For example, accommodating a wide variety of parts requires equipment to do die-attach material dispense, die placement, and wire bonding. Then there’s the specialized equipment and processes for encapsulation, drying, thermal and UV curing, custom fixtures at multiple stages, singulation equipment, and test systems.

Today, I can say without a doubt that our investment in heterogenous assembly has been well worth it. Every day we help our OEMs customers bring products from proof of concept to full production in the fastest and most cost-efficient way possible. How can we help you?

Concept to Commercialization

Whether you need short-run proof-of-concept prototypes, high-volume production, or a second-source manufacturer, Promex can help. Reach out to us and let’s have a no-pressure conversation about how we might help advance your project to success.