Case study

Turning a Sketch into a Production-Ready Module

Problem:

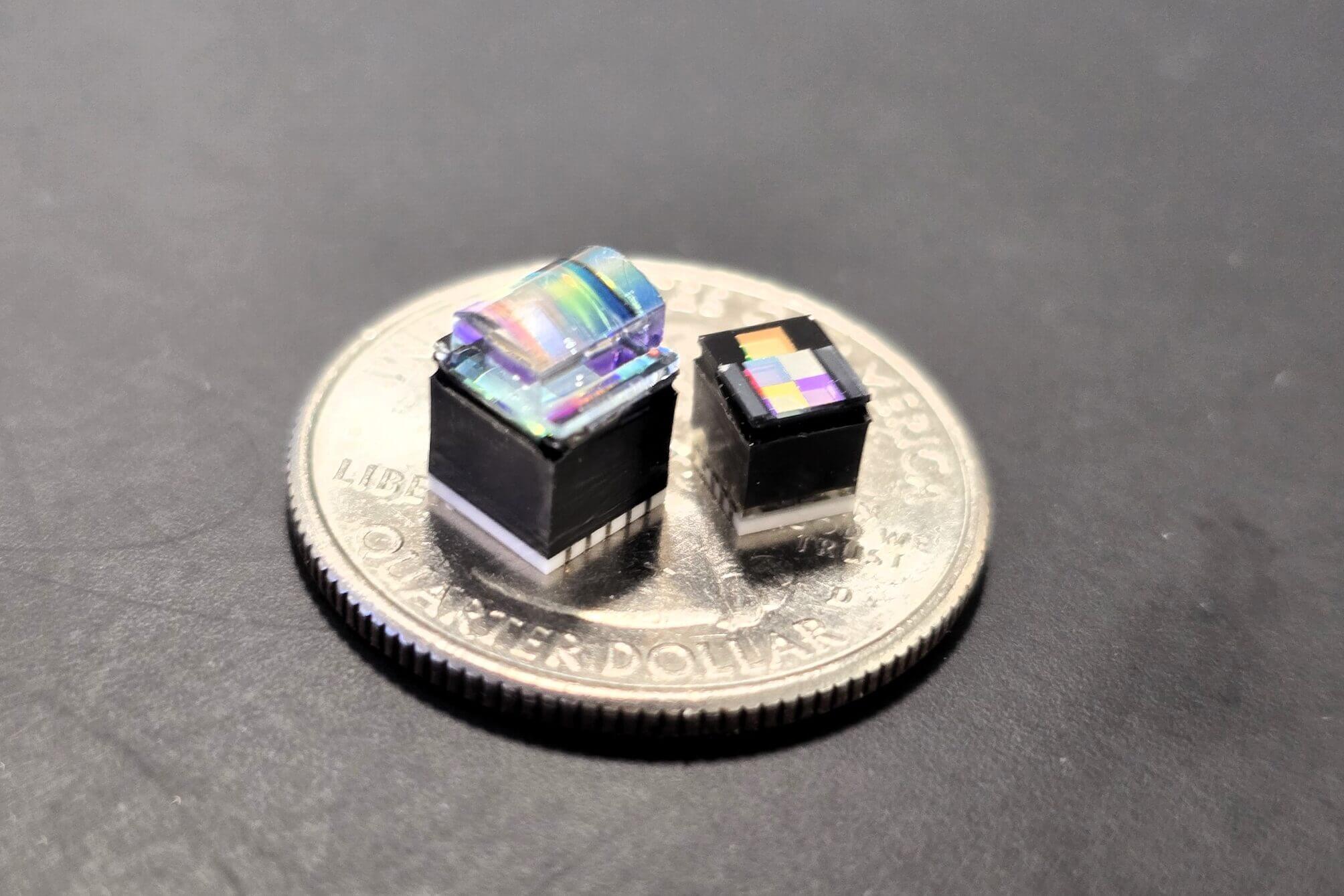

A medical device customer approached Promex with a complex packaging challenge: To meet demanding cost, size constraints, environmental durability and reliability requirements with high performance, they needed to assemble an optical detection system comprised of two multi-die structures on a leadframe, incorporating multi-millimeter thick optical structures using specialized materials free of bubbles and integrating tiny optical components. The design also called for: (a) precision handling of LEDs, photodetector die, surface-mount components, and miniature optical components; (b) sawing of exotic materials to meet final design requirements; (c) integration into a finished detection assembly incorporating a rigid flex PCB. Off-the-shelf solutions weren’t an option—this required custom innovation.

Solution:

What began as a sketch on a whiteboard quickly evolved into a hands-on collaboration with Promex’s CTO and engineering team. Using our in-house expertise, we:

- Transformed a unique leadframe concept into a manufacturable thick-film ceramic substrate, designed and fabricated internally.

- Conducted design-of-experiments impacting multiple, 3-dimensional elements of the two devices comprising the optical system so the customer could experimentally determine a final design allowing the optimal performance window.

- Developed a custom assembly flow that included component fabrication, exotic materials sawing and structure definition using precise wafer saw technology, exotic material sawing, die attach, and bubble-free dispense and dam-and-fill processing.

- Provided die attach and bubble-free dam-and-fill processing before SMT of the finished subassembly onto a rigid flex PCBA.

- Created detailed Manufacturing Process Instructions incorporating high-throughout, in-process checks of critical-to-quality features.

- Scaled the manufacturing process concurrent with the customer’s aggressive product design cycle needs.

Iterative builds refined the design and process—allowing the customer to remain closely involved every step of the way.

Result

The project moved successfully from concept to reality. What started as an idea on paper became a fully functional assembly, meeting the customer’s strict optical, thermal, and complex top-level product requirements. The final module was ready for production and Promex was able to deliver high performance parts for a demanding application.