Process Development & Project Management

At Promex, we guide end-device development from concept through production using our proven Phase Gate Process, providing a structured approach to streamline your complex microelectronic component assembly builds—all from a single trusted source. We can support everything from short prototype runs, to pre-production devices, and scale to large-volume domestic production.

We will work with your engineering team to ensure your conceptual design will work and your component assembly can be efficiently manufactured with high quality.

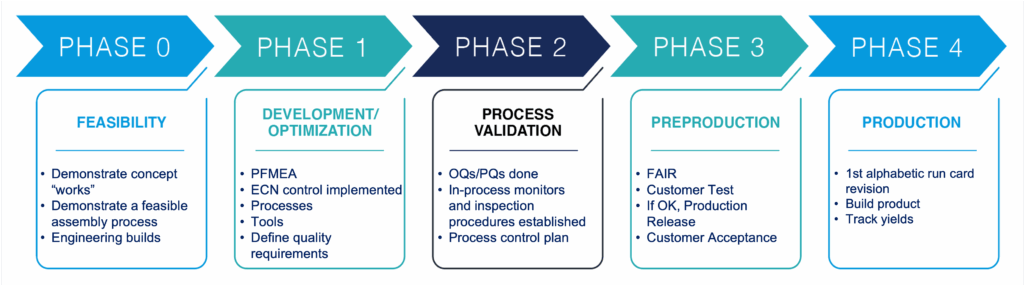

Promex Phase Gate Process

Our Phase Gate Process, key to heterogeneous device assembly, is a complex, multi-stage process that requires careful planning and execution.

Phase 0: Feasibility

The feasibility phase is to demonstrate that a product concept ”works” and can be manufactured at appropriate volume and cost. Engineering prototypes and initial build documentation packages are output during this phase.

Phase 1: Development & Optimization

This is the most important phase. Processes, materials, and tooling will be developed and selected as part of the development and optimization process. The deliverable is a refined, documented manufacturing procedure with recipes, tooling, and in-process requirements using the equipment necessary to fabricate the desired product with a consistency and cost that meets the business needs. This package is suitable for the process validation activities of Phase 02 with minimal, if any, changes. Process Failure Mode and Effects Analysis (PFMEA) is started.

Phase 2: Process Validation

At least three lots are built using the process from Phase 01. All devices meet requirements defined in Phase 01 for the process to be validated. The PFMEA is iterated upon and finalized, and the Process Control Plan is generated. Operational qualification (OQ) and performance qualification (PQ) protocols are written and executed.

Phase 3: Preproduction

Preproduction is a transition state where production-level practices are followed while some of the quality deliverables and documentation are completed. The First Article Inspection Report (FAIR) is completed, and reports are submitted to the customer for approval.

Phase 4: Production

In this final phase, the processes to fabricate an assembly have been developed, validated, and fully documented to both the customer’s and Promex’s satisfaction. The only remaining activity is to accept orders, build product, track yields, and report back to the customer as required.

Long-Term Production

Leverage our Phase Gate Development process to create a customized manufacturing solution for your complex device. We develop, document, and validate the process to meet all regulatory and/or customer requirements and ensure customer satisfaction. Once validated, we build your devices in full compliance with this process, ensuring consistent, long-term production quality.

If you have a product that you need to bring from proof of concept to full production in the fastest and most cost-efficient way possible, we can help you get there.

Project Management

Promex works with you to conceptualize and complete your design, managing the project from beginning to end. Our solutions are tailored to meet your needs—customers that benefit from our project management services include startups, mid-sized companies transitioning to full-scale production, large medical-device firms and defense contractors. Our focus on time-to-market efficiency ensure well-defined deliverables and clear ownership through the product lifecycle, from engineering, process development and optimization, to qualification and production release.

Document control is the backbone of an effective quality management system. Along the way, Promex documents all steps taken to ensure process repeatability and manages needed documentation throughout our Phase Gate Process. Your complete documentation is controlled by one team under one roof, capturing all aspects of the project, including risk assessment, quality control, validation plans and supply-chain management.

Project Management

Effective project management is crucial for all markets, ensuring that projects are completed on time, within budget, and to the highest quality standards. Our project management services offer several key benefits:

- Risk mitigation: Identifying and addressing potential risks early in the project lifecycle to prevent issues and ensure smooth execution.

- Resource optimization: Efficiently allocating resources to maximize productivity and minimize waste.

- Clear communication: Facilitating transparent communication between all stakeholders to ensure everyone is aligned and informed.

- Continuous improvement: Implementing feedback loops to continuously improve processes and outcomes.

Turnkey Services

Promex offers comprehensive turnkey services for components, managing everything from procurement to inventory planning/management and final assembly. You can depend on Promex to utilize vendors on our Approved Vendor List (AVL) or ask us to employ your existing vendors for custom bill of material (BOM) components, leveraging your completed qualification protocol. This ensures seamless integration and simplifies your supply chain, allowing you to focus on your core business activities.

For medical/biotech applications, we can provide a Master Validation Package (MVP), a complete process validation documentation package that conforms to FDA 21 CFR Part 820 and ISO 13485:2016. Our MVP document package includes:

- Process Failure Mode and Effects Analysis (PFMEA)

- Process Control Plan

- Process IQs, OQs, PQs—protocols and reports

- First Article Inspection Report (FAIR)

- Other pertinent precursor documents

Finally, Promex collaborates with your in-house test team or one of our trusted partners to meet all your testing needs. Many of our customers choose to consign and install specialized testing equipment to our facility, where it is operated by Promex’s trained test personnel. Data is collected and uploaded in real-time, enabling yield monitoring and providing immediate feedback to the production floor for continuous process improvement.