Our Capabilities

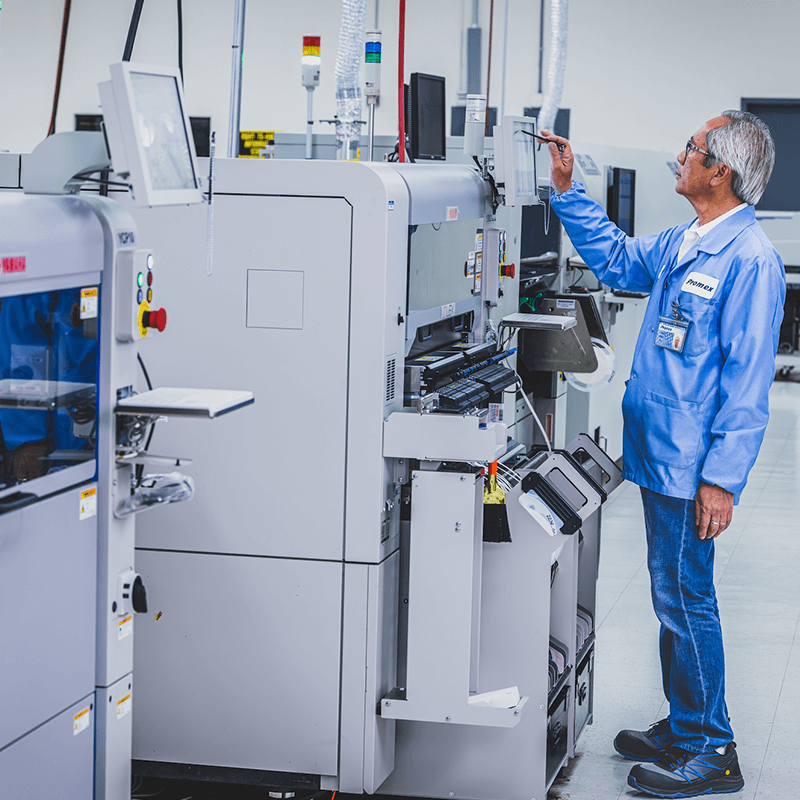

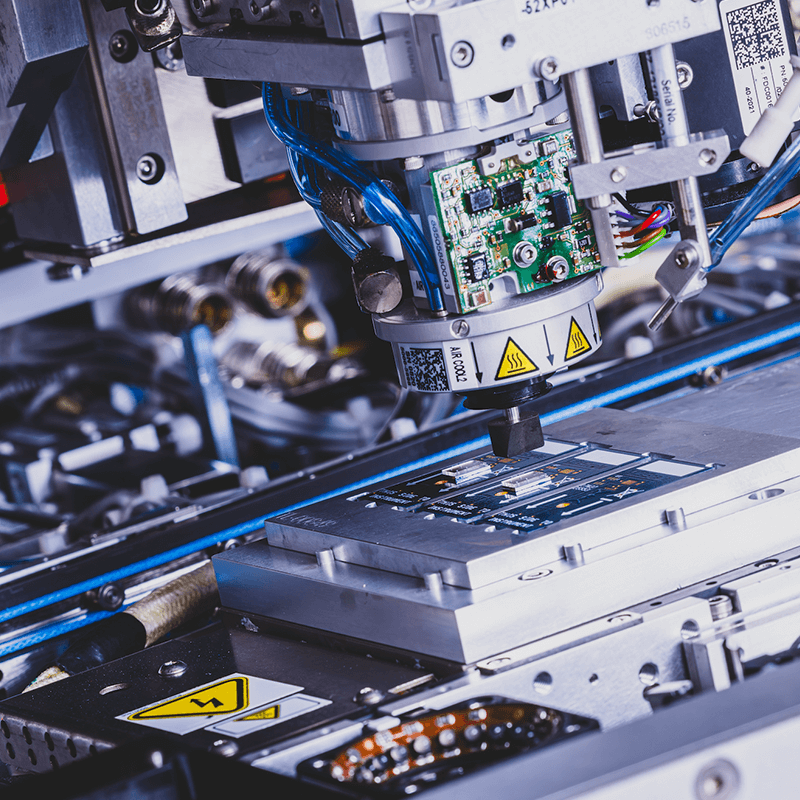

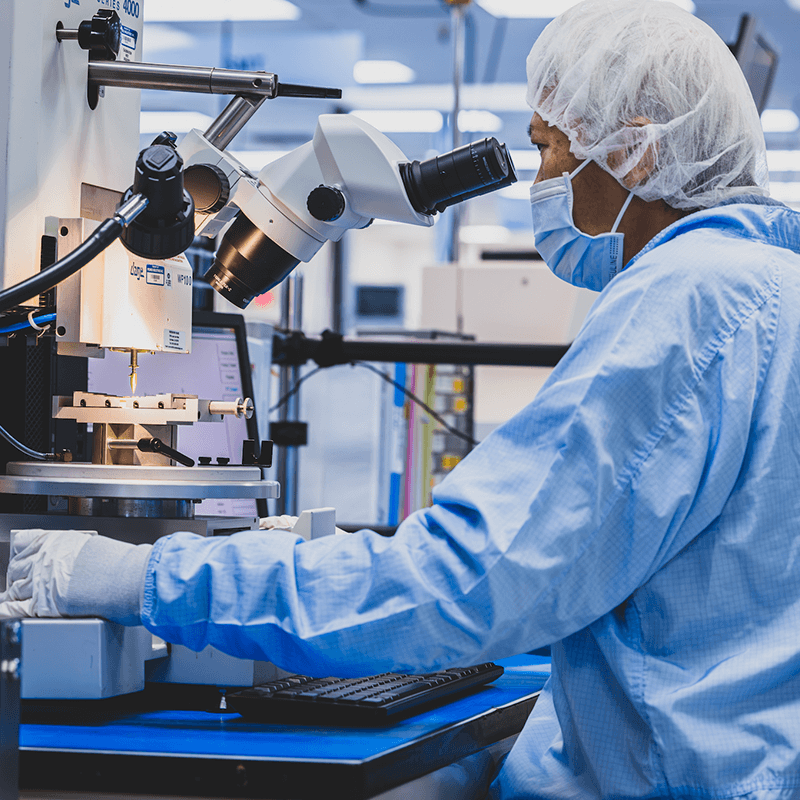

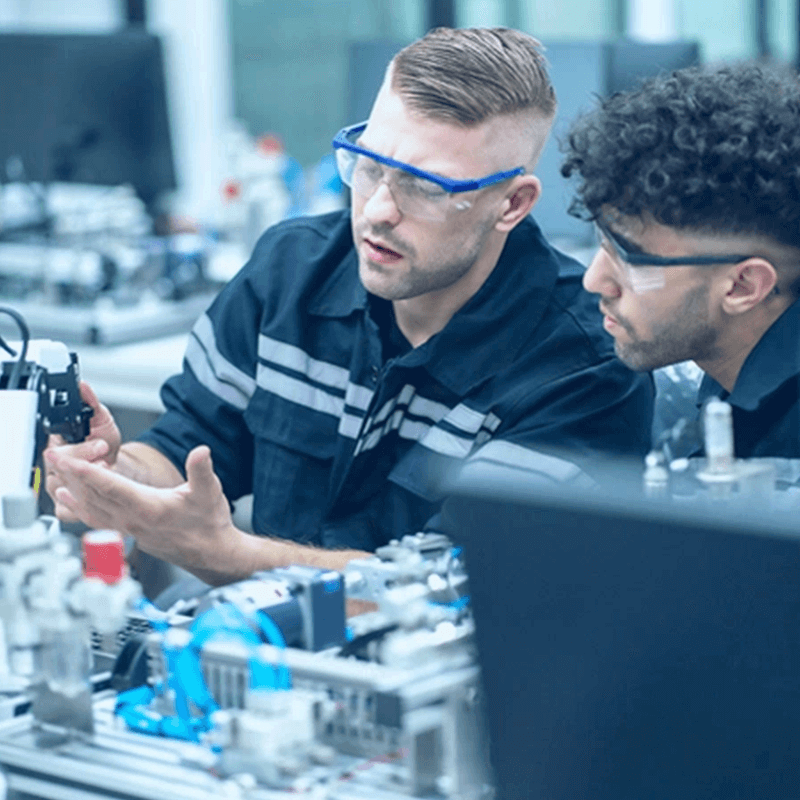

At Promex Industries, Inc. we specialize in advanced manufacturing design, packaging and assembly services for key subsystems that are used in a wide range of applications, such as diagnostics, life sciences, medical and MEMS devices. We are skilled at heterogeneous integration (HI) of tiny components with unique functionality and complex, custom or detailed assembly requirements.

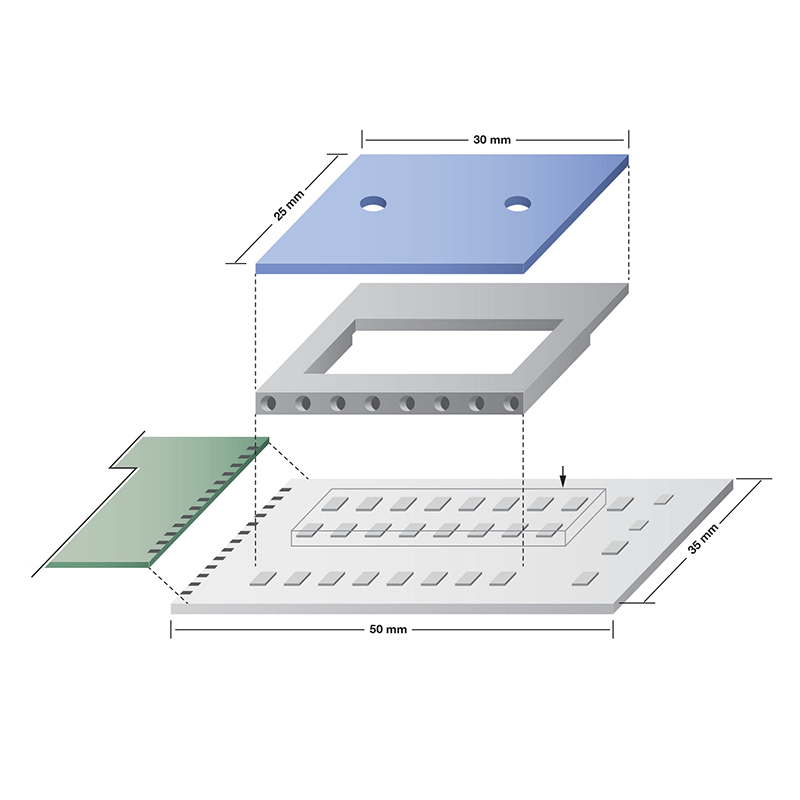

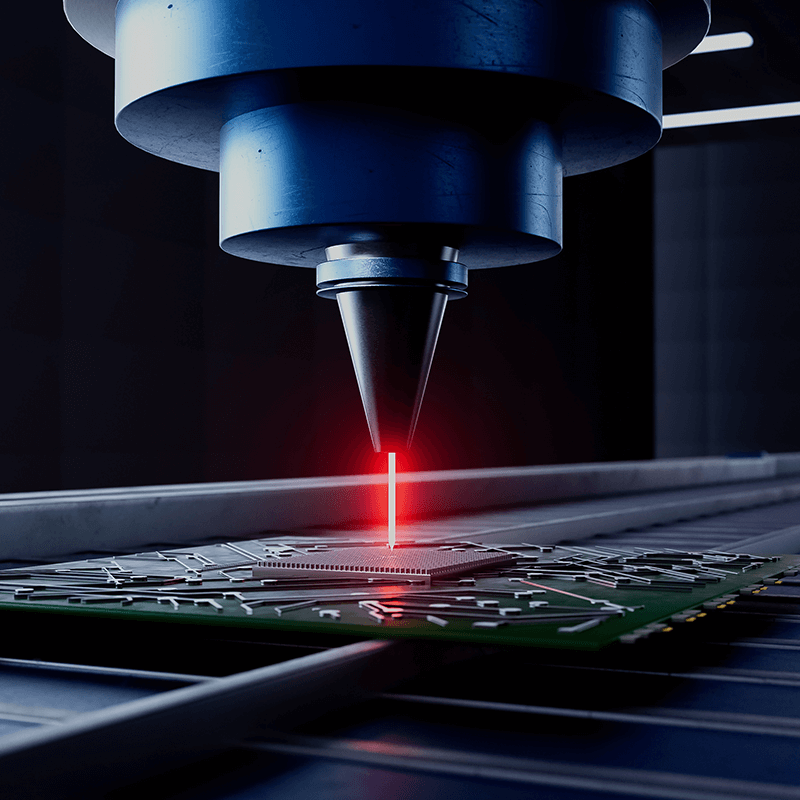

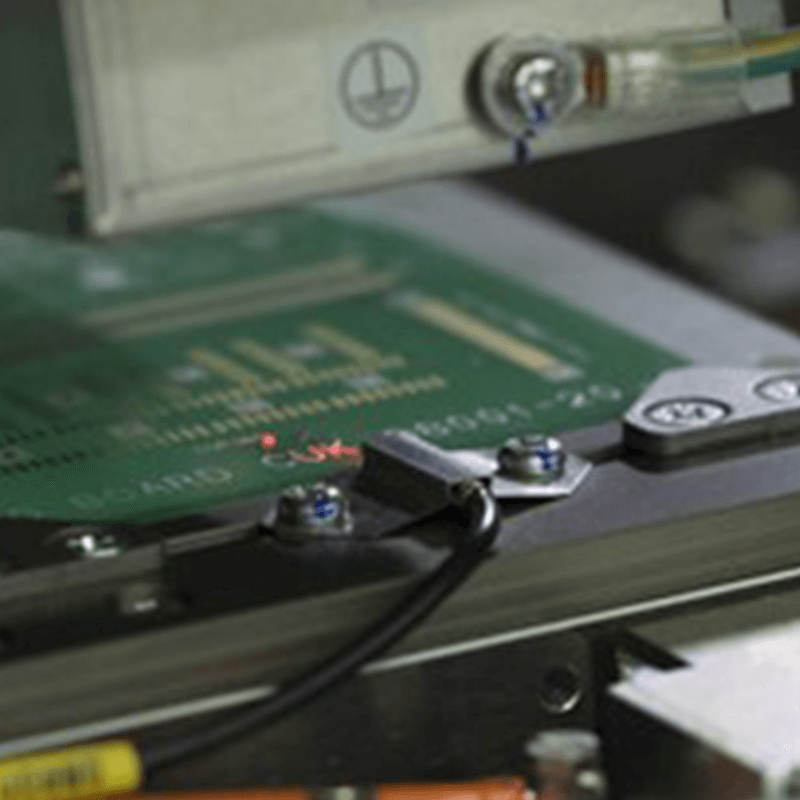

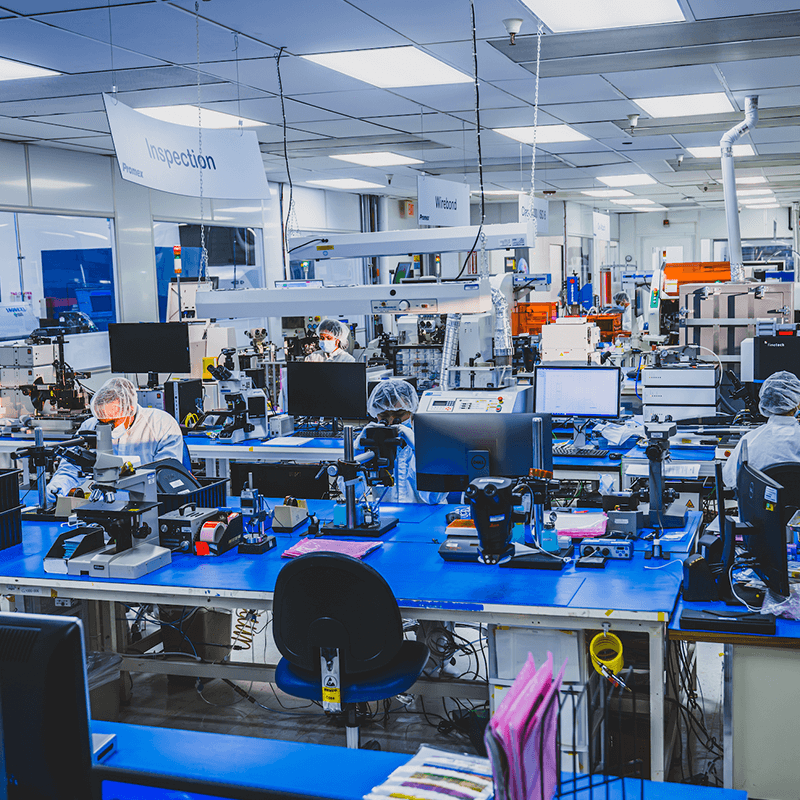

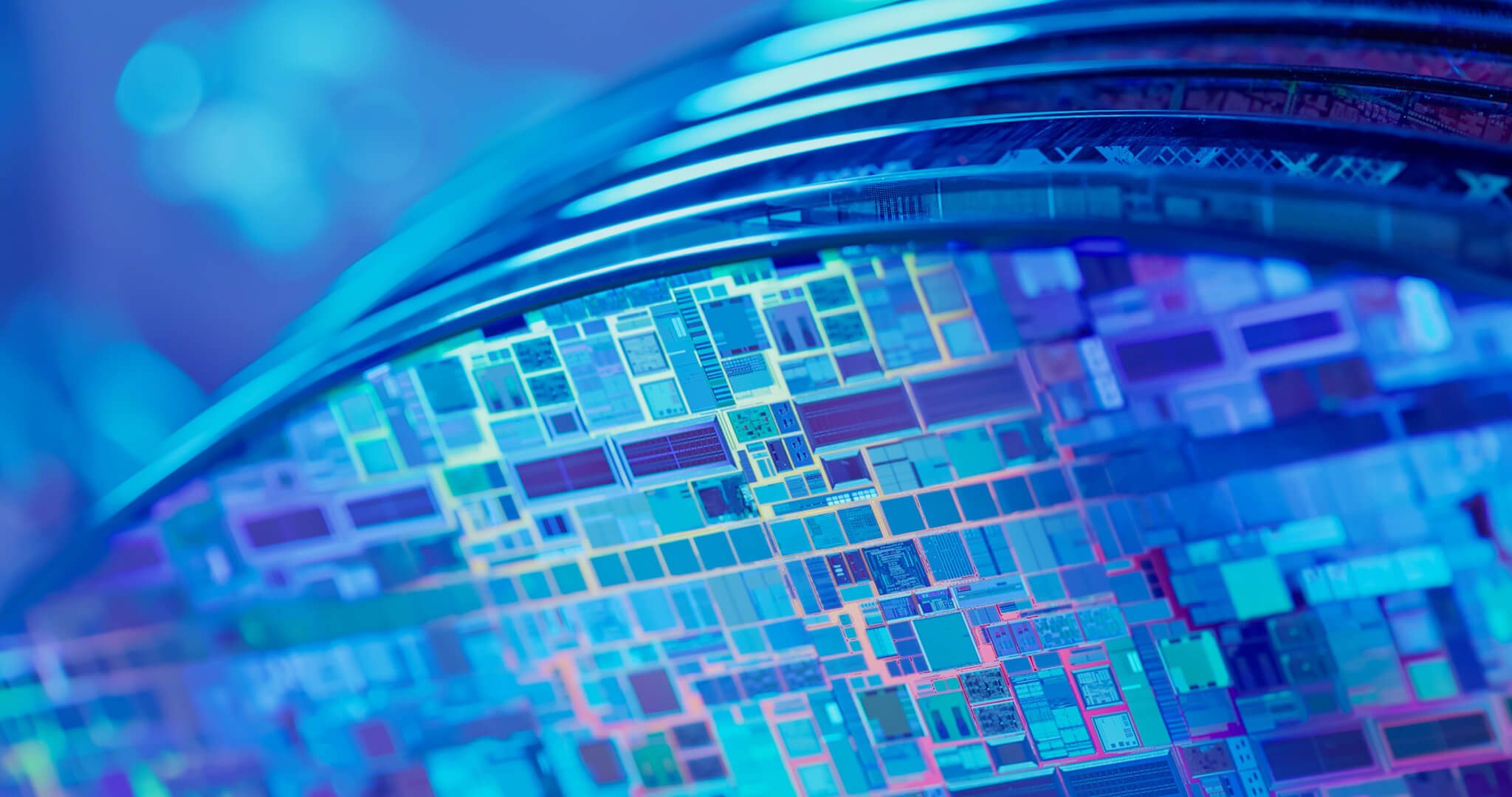

To produce these miniaturized devices, we combine multiple assembly technologies in a cost-effective way, using rapid manufacturing process development to minimize your time to market. During production, we ensure quality and consistent on-time delivery by collocating our services within one factory under a unified quality system. We implement sophisticated HI processes to ensure your complex device is manufactured as efficiently as possible. Offering a range of assembly services, from SMT to wafer thinning and dicing, die bonding, substrate development and metrology, we’ll manage your entire project from start to finish.

We develop customized process flows to assemble a mix of electronic parts and non-electronic parts without damaging the non-electronic items, such as optical components (including filters, lenses, and waveguides), piezoelectric devices, devices with on-board chemistry, fluid channels, devices with tight thermal restrictions, and other non-standard or specialized requirements.

We maintain a broad variety of assembly tools and capabilities which we use to create robust assembly process flows. Our extensive metrology capabilities and technical expertise ensure requirement compliance throughout the manufacturing process and accelerated failure investigations.

Since 1975, Promex has served a variety of clients across the industries of medical & biotech, automotive, military and defense, data and telecom, and more. We operate 30,000 sq-ft production facilities, complete with Class 100 / 1000 cleanrooms, and we are certified to ISO9001:2015 and ISO13485:2016.